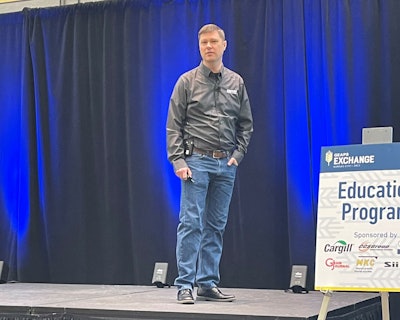

Matt Zabel, system architect for Faith Technologies in Menasha, WI, outlined how energy management systems in grain elevators can pay for themselves at a GEAPS Exchange educational session in Kansas City, MO.

Zabel said companies should monitor their facility's gas and electrical usage to avoid power factor penalties, but many companies object to investing in another software package and training program. In reality, investing in power quality metering (PQM) and trending can save users anywhere from 3% to19% on their energy bills.

Companies overpay for energy when they don't optimize their operations for peak run time or when they have unexpected downtime due to power outages. Common indicators of power quality issues that could lead to outages include:

- Drives and LED light fixtures prematurely failing

- Equipment stopping without being turned off

- Flickering lights

- Damage to computer equipment

- Poor power factor

"Power quality meters help users with alarms for outages and notification of acute underlying electrical issues to prevent downtime," Zabel said. In the absence of data from an onsite PQM, Zabel suggested hiring a service provider to conduct a power quality study that may conclude with recommendations such as:

- Lowering system harmonic distortion

- Rebalancing loads

- Propping up voltage during sags

- Correcting electrical power factor

Click here to learn more about managing and utilizing energy data to optimize facility operations.