United Cooperative, a member-owned cooperative headquartered at Beaver Dam, WI, will begin construction on a multi-structural manufacturing facility in Waupun, WI, this year.

The company is planning a three-phase expansion project to create state-of-the-art manufacturing capabilities, marketing opportunities and technology advancements to meet the demands of Wisconsin’s agricultural landscape.

Processing facility to aid sustainable farming efforts

According to United Cooperative, as consumers request more knowledge about food origination, agricultural producers seek to find ways to provide high-quality, safe, and traceable feed products for their growing farm operations.

These sustainable farming efforts will ensure consumer confidence now and into the future, said John Scheuers, United Cooperative Feed Division vice president. Feed manufacturers like United Cooperative require state-of-the-art facilities to meet the quality requirements, efficient operating standards, and safe and secure supply chains for our food supplies.

“New Safe Food, Safe Feed regulations require feed manufactures to comply with quality control measures that are not possible with outdated feed mills,” said Scheuers.

“As a result, United Cooperative’s investment in this new Waupun facility will enable us to meet these new regulations and the ever-changing demands of our members.”

State-of-the-art design

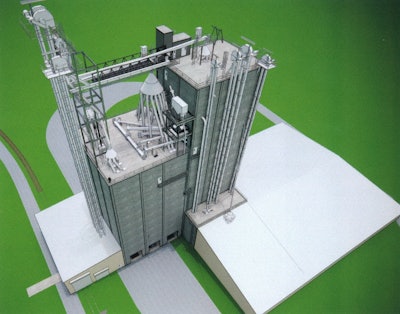

United Cooperative’s Waupun feed and grain manufacturing facility will have capabilities that include high-speed loading and unloading of ingredients, high-speed roller-grinders, pelleting capability, steam flaking, micro-system, both bagged and bulk texturized calf feed manufacturing, mineral manufacturing, and operations managed by a computerized control system for quality control.

“Our goal is to manufacture 23 tons of feed every 15 to 20 minutes, depending on the number of items in the mix,” Scheuers added.

This new state-of-the-art feed and grain facility will also be able to take advantage of rail for our inbound and outbound needs, thus limiting supply chain issues caused by the trucking industry.

“The Waupun facility will support new grain marketing opportunities for our member-owners and cover the demands of increased corn and soybean yields,” said Al Jentz, V.P. of Grain for United Cooperative.

Soybean crushing, processing facility

In addition to the feed and grain expansion, the third phase of the construction project will be a state-of-the-art soybean crushing and processing facility.

When operational, this plant will crush 7.5 million bushels of soybeans annually. This plant will supply both soybean meal and soy oil and bring the surrounding counties into a global ag economy. The Waupun project will create 50 high-quality jobs.

“This construction project is essential to our growth initiatives and our promise to our member-owners that they can rely on us for their agricultural needs,” said David Cramer, president and CEO of United Cooperative.

Along with the Waupun facility, United Cooperative has six other state-of-the-art feed locations and 20-grain locations strategically placed throughout Wisconsin, where it manufactures and sells feed and grain products and services.