Each year at harvest as grains make their way toward finished products, mycotoxins pose several challenges for various feed and grain industry players. As these stakeholders work to ensure they meet safety and quality regulations for human and animal consumption, they need access to rapid, robust and user-friendly analysis methods. These solutions will help make more effective and efficient mycotoxin screening possible for everyone from farmers, traders, elevators, grain processors, feed manufactures, pet food and grain-based food producers.

Today, many technologies are available to aid mycotoxin monitoring and detection.

Moisture meters are a preventative measure, helping elevators dry grain efficiently. Rapid lateral flow testing strips are the first line of detection, with automated ELISA, high-performance liquid chromatography (HPLC) and liquid chromatography-mass spectrometry (LC/MS/MS) being used for more sensitive confirmatory testing.

The key is to leverage analytical tools and best practices that are adaptive and responsive to each feed and grain player’s unique needs and technical abilities. These approaches will help them pivot and respond to ever-rising regulations and each harvest’s unique weather conditions.

Testing challenges and agile solutions

Mycotoxins are toxic compounds naturally produced by certain types of molds. Recent research suggests that there are up to 400 types of mycotoxins known today1. It is beneficial to use testing and analytical technologies to handle multiple mycotoxin screenings with various threats in a streamlined and effective way.

Additionally, regulatory maximum limits in the industry can vary between countries, so it’s crucial to employ analytical testing solutions that cover all ranges, including sourcing and export considerations. Furthermore, fluctuations in the weather, exacerbated by climate change, are among the main factors associated with the wildcard of mycotoxins in the grain industry.2

To address these challenges, stakeholders throughout the feed and grain industries need access to accurate, powerful and intuitive testing technologies.

Following are some best practices to keep in mind at each stage of the workflow to meet the intense demands from both regulators and mother nature.

In-field monitoring and screening

At the early stages of mycotoxin monitoring, farmers can use moisture meters in the field to monitor grain moisture content as it comes off the field. They can then use the meters to monitor grain drying, thereby mitigating mycotoxin growth risks while also optimizing the costly energy use of the dryers.

When moving to the grain elevator, speed and accessibility are of utmost importance. A popular solution is screening crop samples with rapid lateral flow (LF) test strips to provide quantitative results in minutes.

Test strips offer a great first-line defense against mycotoxin contamination and can identify all the major mycotoxin classes. As mycotoxins are chemically and thermally stable, they can survive further processing through to the final product stage, therefore, catching them early in the process is key.3

These initial interrogations provide a first data point. The next steps and decisions can start to be considered, such as doing additional testing.

Taking it to the next level

Once a crop shows mycotoxin contamination, testing frequency ramps up significantly. Here enters automated ELISA testing. This type of testing requires slightly more extensive preparation and analysis methodologies than LF but allows for rapid screening of multiple mycotoxin classes simultaneously. As this usually requires specific in-lab training, ELISA testing is conducted at large processing facilities or outsourced to a contract or corporate lab facility.

By outsourcing, stakeholders at this point in the grain workflow can increase their testing capacity by using high-throughput and automated testing solutions. Alternatively, by leveraging these solutions in-house, processors have access to an enhanced understanding of their raw materials.

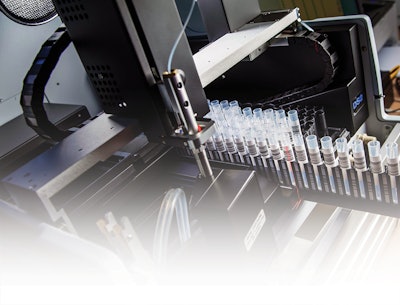

Like using LF strips, ELISA tests for the presence of a single analyte per extracted sample. By installing an automated liquid handling instrument, however, multiple mycotoxins analytes are tested simultaneously, significantly cutting the time of manual workflows.

Automated solutions can also perform steps beyond extraction, including liquid handling, washing, incubation timing, plate reading and automatic report generation. This workflow results in a large reduction of hands-on time for technicians and greatly reduces the risk of human error.

To help streamline automation efforts, work alongside a full technology and support provider to assist its customers across the entire testing workflow. For example, PerkinElmer has helped a feed and grain processor use automated ELISA testing to run 192 tests for a single analyte — including standards — in less than 90 minutes. Previously, they ran 50 to 60 samples a day against a total need of 800 to 4,000 sample tests over the entire harvest period. This example demonstrates how automation can increase throughput and reduce labor usage for bigger corporate or contract laboratories.

Additionally, the cost per sample is reduced to the same level as LF strip testing while yielding a higher-level result. Rental testing solutions just for harvest time are also possible, creating even stronger cost/benefit ROI for organizations.

Multitasking

Finally, for labs that want to do more sophisticated testing for mycotoxins at lower limits and want the flexibility to test for other analytes with one instrument, HPLC and LC/MS/MS can be used. These advanced methods are highly sensitive and scalable. For example, HPLC and LC/MS/MS can detect all mycotoxin classes present from just one extraction. These instruments can also measure other analytes, including the quantification of vitamins, amino acids or allergens. All these benefits reduce cost per sample even further and increase efficiencies in the workflow.

At this stage, facilities usually outsource testing to contract labs or have them handled by larger corporate labs. To keep up with high demand, these labs can invest heavily in automated technologies which provide efficient, high throughput solutions that allow for the analysis of more samples in less time. Furthermore, during peak seasons, these labs may also consider renting additional technologies to meet the demand.

Testing for the future

Optimizing mycotoxin testing at every point of the processing workflow and with every stakeholder in mind can help drive and maintain global food safety. Feed and grain companies can optimize mycotoxin testing by leveraging and employing technologies and methodologies that keep pace with the ever-changing weather conditions and regulatory limits. Adopting rapid, robust, and user-friendly analytical solutions can assist in safeguarding the feed and grain industries and their consumers against mycotoxins.

The future of these solutions lies in automation. Yielding accurate results at higher throughputs and lower cost per sample helps maximize output, repeatability and overall confidence to meet stringent regulatory limits.

Working closely with a solutions provider can be extremely beneficial. One of the easiest ways to do this is by partnering with a single-source vendor who can deliver expertise and support at every stage. These providers often offer peace of mind, with testing solutions that are both accredited by regulatory bodies and cover all ends of the variable regulatory limits across the globe. ■

References

- Berthiller, F., Sulyok, M., Krska, R. & Schuhmacher, R. Chromatographic methods for the simultaneous determination of mycotoxins and their conjugates in cereals. Int. J. Food Microbiol. 119, 33–37 (2007).

- Gruber-Dorninger, C., Jenkins, T. & Schatzmayr, G. Global Mycotoxin Occurrence in Feed: A Ten-Year Survey. Toxins 11, 375 (2019).

- Karlovsky, P. et al. Impact of food processing and detoxification treatments on mycotoxin contamination. Mycotoxin Res. 32, 179–205 (2016).

AUTHORS

Mark MacBeath, Food Safety Product leader, and Wes Shadow, Global Market manager — Grain at PerkinElmer, Inc.