MPI was awarded Best of Show at the International Association of Operative Millers (IAOM) 126th Annual Conference and Expo.

During the Product Showcase, MPI demonstrated the newly patented Intell-I-Mag® magnetic separation equipment.

“We are honored to win the coveted prize for the best Product Showcase,” said Frank Reda, MPI Sales Manager – Americas.

“We are committed to developing innovative solutions of magnetic separation equipment for the benefit of industry and society.

"We are grateful to be recognized by milling and allied trade professionals for this award and for the many good friendships that we have cultivated throughout the years of participation in the IAOM.”

Intell-I-Mag offers the milling industry and other food producers an effective method to improve their product quality and comply with ever increasing quality monitoring and reporting standards. Factory automation processes and product throughput are significantly improved when using Intell-I-Mag. Intell-I-Mag will change the way millers use magnetic separation equipment.

Data drives performance for intelligent magnet

MPI’s Intell-I-Mag® was recently introduced to the grain industry at GEAPS Exchange in Kansas City in March as the next step in magnetic separation innovation and facility automation.

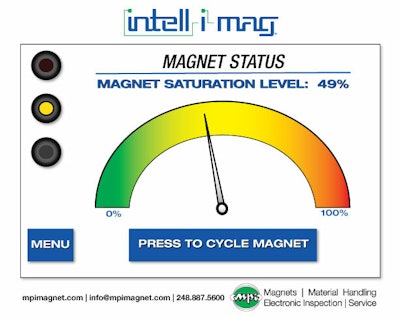

Intell-I-Mag is the first intelligent magnet to self-monitor ferrous metal saturation in real-time and log system data.

The patented Intell-I-Mag monitors ferrous contamination of incoming ingredients, detects equipment malfunctions before scheduled cleanings, ensures fully saturated magnets are cleaned before metal events occur, reduces shutdowns for premature magnet cleaning, and ensures the separator is always working at peak performance, capturing weakly magnetic materials such as work-hardened stainless.

“Intell-I-Mag™ delivers an innovative solution for manufacturing facilities impacted by industry-wide labor shortages and cost increases,” said Kyle Rhodes, vice president – Business Development.

It also helps reduce challenges due to equipment failures, inadequate magnet cleaning intervals or inaccessible magnetic separation equipment.

Data-driven feedback on cleaning cycles and magnet performance increases production line up time and promotes peak performance of magnetic separators, reducing the risk of a metal event.