In the latest Feed & Grain reader survey, 65% cited labor shortages as the leading threat to their business. This is no surprise as labor shortages have myriad consequences for feed and grain businesses, ranging from reduced operational efficiency to compromised quality control and delayed technological advancements, all of which negatively impact the bottom line.

Our results align with a recent survey commissioned by RSM, a global network of assurance, tax and consulting firms. Nearly all respondents in their middle market companies survey said hiring is a top challenge. Recruiting into agribusinesses has become increasingly difficult with increased competition for skilled workers and their higher expectations for employers.

Fewer workers with higher standards

A massive wave of Baby Boomer retirements over the last three years has contributed to today’s reduced workforce. Between February 2020 and June 2021, about 1.1 million Boomers retired. By comparison, the number of retired Boomers increased by only about 250,000 in the previous year’s February to September period.

Our survey respondents’ average age was 60 years old, signifying the need within five years to replace a large deficit of feed and grain operations managers and agribusiness executives. Factor in burn-out by remaining employees who are spread too thin, and it’s a perfect recipe for high turnover.

Meanwhile, recruiters have discovered that appealing to prospective new hires in Gen Z requires more than high wages alone. Today’s workforce is seeking flex-hour options, enhanced benefits packages, on-the-job training and sign-on bonuses that companies facing tight margins may not be able to offer.

With these factors in play, automating roles will be key to increasing productivity and profitability for grain and feed businesses.

How automation addresses the threat of labor shortages

1. Increases production efficiency

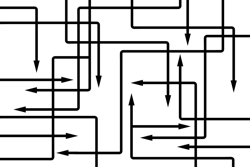

Automation controls can be integrated into operations from receiving to loadout, allowing multiple processes to run at once with less staff. Automated conveying and material handling systems streamline the movement of materials within a facility, helping to maintain consistent production and flow rates. This reduces the risk of bottlenecks and downtime common with manual process that rely on labor to operate.

Automated batching is one of the most useful labor-saving applications in feed manufacturing. For example, micro ingredient systems can accurately measure, add and blend micro ingredients with major and minor ingredients into batches, minimizing the risk of human error and product waste from spilling. Re-programmable control interfaces also make it possible to change batch recipes without significant downtime.

2. Enhances feed quality control

Quality control can be automated to require less labor by instead using sensors and monitoring systems to continuously measure and adjust factors like temperature, humidity, and ingredient ratios — ensuring precise and consistent execution of production parameters. Data collection for ingredients and products can also be automated to improve data uniformity and precision, while preventing issues like excessive moisture or aflatoxin contamination in finished products.

Automated quality control systems can offer reminders and checkpoints for essential tests, reducing the likelihood of being skipped due to time constraints or distractions. This mechanism serves as a safeguard against both unintended and deliberate mistakes. For example, an automated reminder to confirm aflatoxin testing upon receiving a corn shipment enhances the likelihood of identifying and addressing contaminated ingredients. Automation can also track ingredient lots to aid in recalling product that may have been manufactured from bad ingredients. With automation enhanced testing combined with automated track and tracing, problems with ingredients or products can be addressed more quickly and reliably than ever before.

3. Monitors and controls processes remotely

The latest automation systems are often equipped with remote monitoring and management capabilities. Faced with labor shortages, remote monitoring is key to enabling a smaller team of skilled operators to manage multiple aspects of production without being present inside the mill. For example, from a centralized location, automation systems can manage ingredient bin assignments between production centers to ensure products are always drawn from and routed to the correct bins.

Some automation providers offer mobile features, in which operators can receive alerts, adjust parameters, and troubleshoot equipment issues all from a cell phone, minimizing downtime despite the size of the workforce. This feature also allows production managers and operators to monitor and control multiple manufacturing processes simultaneously.

Skilled labor shortages pose a significant threat to agribusinesses. But investing in automation can help restore productivity losses by improving efficiency, enhancing quality control and enabling remote facility management.

Furthermore, technology is one sector that seems to have more employees than necessary. Expanding into automation will increase the need for tech roles in agribusiness, potentially allowing the feed and grain sector to tap into this deep talent pool.