Bunge, an agribusiness and food ingredient company based in the U.S., is dedicated to improving the global food supply chain. Its facility in Woodland, CA, wanted a complete and convenient way to achieve on-demand flow when handling rice bran in its bulk bag filling operation/process.

The rice bran, however, was clumping in their hoppers and silos -– a common issue for materials that hold moisture and are sensitive to humid environments. Workers had to hammer the vessels, which was ineffective and stressful for everyone in the factory.

“It was like fingernails on the chalkboard. You wanted to get away from it,” says John Pappenheim, Bunge’s maintenance manager. “It also damaged the equipment and posed possible injury to employees.”

The company was planning to set up a new bulk bag filling station, so it needed to improve material flow to keep up with the filling operation.

The Solution

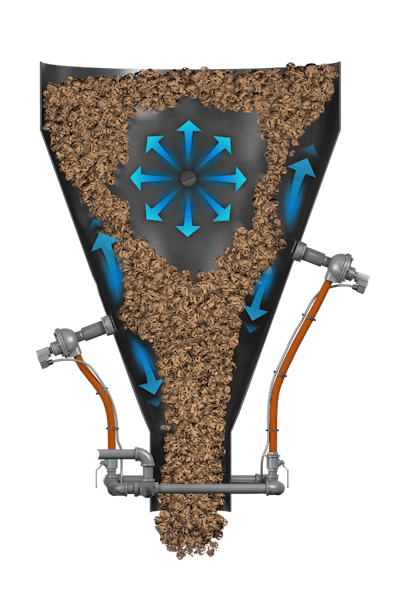

After reviewing its options, the company chose to install the AirSweep system.

Four AirSweep® VA-06 units were placed 90 degrees apart on the sloped walls of the rice bran bin. The VA-06 Airsweep was ideal for this application as the 3-foot-sweep-diameter would cover each of the four sloped walls perfectly in the customers’ vessel.

Installation was simple and inexpensive. The couplings were pre-attached to the vessel, so it was just a matter of threading the AirSweeps into position and connecting to the existing compressed air and electrical system.

“Any electrician can wire it up," says Pappenheim. "Everything was straightforward. I would absolutely recommend it.”

It was equally easy to order parts and accessories.

“When we needed extra parts, Control Concepts’ customer service was extremely helpful and fast," says Pappenheim. "If we had to get those parts from China, it may have taken months to get them."

After seeing how well AirSweep® worked on rice bran, Bunge has incorporated the system in their masa flour factory for a cyclone application.

Like rice bran, masa flour is also prone to bridging and ratholing, however the AirSweep® has proved successful in that application as well.

The Result

The company saw a marked difference in material flow – and worker safety. They have no clumping issues, no dents on machines, no irritating hammering noises. The AirSweep’s soft hiss can barely be heard. It just quietly gets the job done.

Added Pappenheim: “In fact, we are looking into expanding to use in other parts of our plant.”

For more information on Control Concepts, click here.