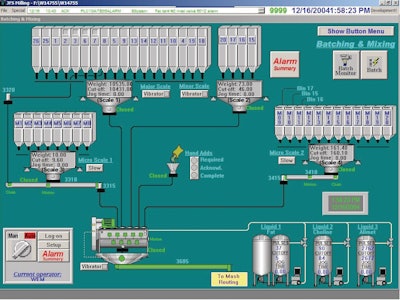

Comco Helm Batching Automation Software

- Automatically adjusting free-fall calculation

- Cross-contamination checking for batches and finished product bins

- View and control batching from any workstation

- Details of all batches are logged

- Utilize multiple feeders

- Material substitutions from either the same or equivalent material

- Substitutions can be made with material from a different scale

- Automated hand adds and pre-weighs

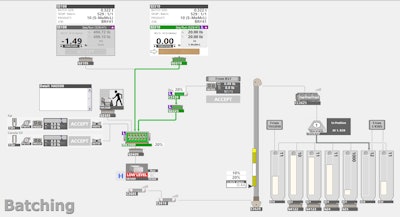

Easy Automation Batching Control System

- Unlimited weighted, metered and/or timed ingredients

- Automatic free-fall, pulse length and high-speed shutoff adjustments at scale or ingredient level

- Customized to facility

- Auto batching, lot tracking, feed tags, flushing and hand-add workstation

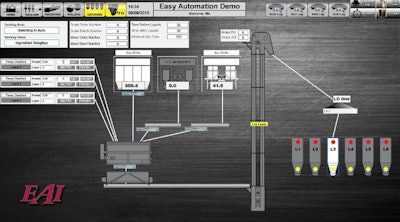

WEM Automation WEM4000 Batching Automation

- Superior batching speed and accuracy

- Meets or exceeds track-and-trace requirements

- SQL server database

- Allen Bradley control and Compact Logix PLCs

- Complete plant control

- Bar code and RFID ingredient lot tracking

- PDA for alarms and hand-adds

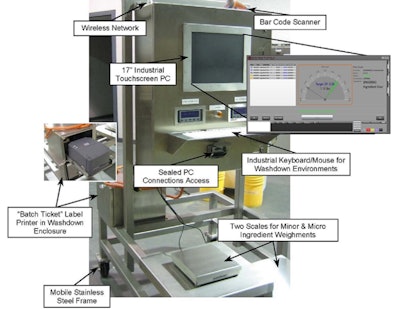

Sterling Systems & Controls Semi-Automatic Hand-Prompt Batching Station

- Designed to eliminate bad batches resulting from operator error and interruption

- Operator involvement through each step of batching process

- Provides automated operator instructions or prompting, ingredient lot tracking, automatic weighing with over/under tolerance control, assures compliance with recipe/formula, etc.

- Real-time records for each batch produced

- Barcode scanner can be provided and attached to batching station

CPM Beta Raven MM4 Batching

- Detailed process records are kept to facilitate process improvement, corporate reporting and regulatory compliance

- Data such as recipes and orders may be imported from a corporate system

- Production records may be exported to corporate system

- Traceability is available for any ingredient, so product made with bad ingredient may be easily identified and recalled

- Ingredient assignments are managed to prevent operator from drawing from wrong ingredient bin or routing to wrong mash bin

- Sequencing prevents recipes from being run in order, which could result in medication or animal protein contamination

Sudenga Industries Model SI-2000 Batching System

- Unlimited formula, group and location information storage

- Group phase feeding lists based on weight on phase, days on phase, weight or days, or both

- Automatic ingredient freefall compensation

- Track inventory on hand and cost of each ingredient