Control Concepts Inc. announced it will provide AirSweep® units to the Kansas State University Bulk Solids Innovation Center (K-State BSIC), as part of a partnership to train students and professionals on how to handle bulk materials. Through this donation, AirSweep -- a material flow leader -- aims to provide professionals with hands-on experience and tested solutions to material blocks.

Designed for on-demand material flow

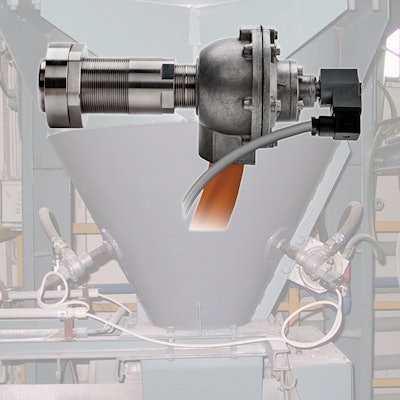

An AirSweep unit will allow instructors to demonstrate efficient handling of bulk solids and other materials with pneumatic flow aids.

AirSweep technology is particularly effective for materials that can’t be handled by fluidizers and other pneumatic flow aids. Each powerful pulse of the AirSweep nozzle directs a high-pressure, high-volume, 360-degree burst of compressed air or gas, which lifts material back into the flow stream.

AirSweep’s ability to work with many types of bulk solids—from powders, pebbles, to dense or moist compounds— will be particularly useful for observing material flow of different materials. Through proper positioning and timed release, it can create on-demand, first-in/first-out flow to prevent stagnation, spoilage, and other issues that affect product quality and production speed.

Empowering the next generation of plant managers and productivity experts

K-State BSIC is the only university-based, unbiased entity in North America dedicated to improving bulk solids handling.

Aside from the classroom unit, AirSweep will also be installed at the Center’s 13,000 square-foot lab. This facility is where bulk test materials flow is tested for clients who come from various industries in the US and around the world.

Todd Smith, business and strategy manager for K-State BSIC, welcomes the partnership between the Center and Control Concepts’ AirSweep.

"We look forward to adding AirSweep to our full-scale bins as well as a cut-away unit for use in demos and short-course education. Our Center has the most state-of-the-art facility for bulk solids research and education, and the Airsweep system is an excellent addition for controlling flow of challenging materials."

Control Concepts Inc. Director of Sales Paul Rose sees the partnership as a strategic move for both institutions.

“AirSweep is a unique material flow aid that stands in its own category. There’s nothing else on the market that can handle wet, sticky and difficult bulk material flow challenges. The addition of AirSweep allows the BSIC to round out the solutions they have on offer, so that their clients can make the best informed decisions for their needs.”

About Control Concepts Inc.

Control Concepts’ material flow systems help reduce risk by keeping materials flowing effectively and reliably through a facility. The AirSweep™ material activation systems activate bulk material up to an 8-foot-diameter to produce a first-in, first-out controlled flow.