Learn about the more commonly used drive solutions from SEW-EURODRIVE for the agriculture industry that help keep the most demanding processes up and running without missing a beat.

Brand Insights from SEW-EURODRIVE

As a tried-and-tested partner in the agricultural industry, we know your applications. Whether you use screw, belt, or chain conveyors, bucket elevators, or rotary gate valves, SEW‑EURODRIVE delivers that all-important added value of drive expertise throughout the entire lifecycle of the system. Here is a deep dive into some of the more commonly used drive solutions from SEW-EURODRIVE for the agriculture industry that help keep the most demanding processes up and running without missing a beat.

Reliable Screw Conveyor Drive

SEW-EURODRIVE’s enhanced screw conveyor drive takes superior performance to the next level. Its four individual sealing areas provide unprecedented protection against contaminants and abrasives. Plus, its taper bearings provide the maximum thrust load capacity required for screw conveyors.

Various motor inputs, two-gear unit styles, and numerous ratios provide maximum flexibility and eliminate the need for belts and sheaves. The SEW-EURODRIVE compact screw conveyor drive is truly the ultimate solution for bulk material handling. With multiple fan designs and diameters housed in one common shroud, the fan cooling can be selected for lower oil temperatures, optimal noise levels, or a balance of both. As in the name, this drive excels with screw conveyors.

Specialized Desolventizer Toaster Drives (DTDC)

.mOXg6tiFMa.jpg?auto=format)

The DT and DC drives from SEW-EURODRIVE are specifically designed to drive desolventizer/toaster equipment that removes the solvent and dries grain material so you are left with a dry and flaky or granular ‘meal’.

The units feature additional bearing support, extra heavy-duty bearings, condition monitoring, and an advanced cooling and lubrication system. The unique design of these drives delivers the power and strength required to meet grain processing demands.

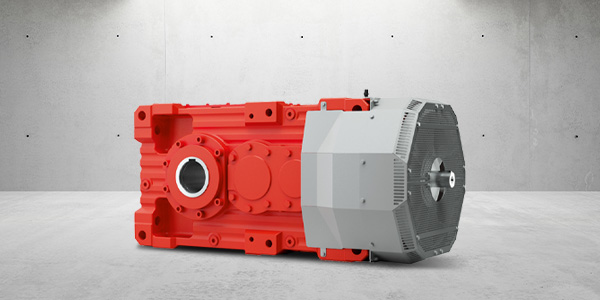

Robust Large Industrial Gear Unit

The next generation of industrial gear units has been introduced to SEW-EURODRIVE’s portfolio of drive solutions. Building off the success of the X-Series helical and bevel-helical gear units, the X.e generation represents an evolutionary step in performance. Developed to the latest international standards with advanced calculations, the X.e gear units have been modeled and then validated in the harshest of conditions, both in simulated laboratories and real-world applications. The results are improvements to everything a user might hope for – increased lifetime, reduced maintenance, and cooler operating temperatures – while maintaining the footprint and mounting geometry of the existing X-Series product. These industrial gear units are often used in heavy industrial belt conveyors, cranes, and mixing applications.

Space Saving Planetary Industry Gear Units

The P2.e Series planetary gear unit from SEW-EURODRIVE offers compact, torque-dense solutions for the agriculture industry.

The P2.e Series is available for a torque range of 24.8 kNm to 124 kNm. These two- or three-stage planetary gear units cover gear ratios of 15.2 to 332. With its compact design, flexibility, and high thermal limit rating, this gear unit is the ideal solution for continuous heavy-duty applications where space is tight. These units can be ordered with or without integral motors, in footed, flanged, or shaft-mounted configurations.

Lifecycle services - We are here for you!

Agricultural logistics is characterized by periods of intense peak activity that can't always be planned. We work hard to ensure your system can meet these stringent requirements and that it works when you need it, whether during startup, repairs, inspection, maintenance or retrofitting the latest technologies. Leave nothing to chance – leave it to the service staff of SEW‑EURODRIVE. With SEW-EURODRIVE’s lifecycle services, you have a personal contact here for you whenever you need them. Our services are an integral part of our portfolio and are closely intermeshed with our products to ensure you can get everything you need from one place!

SEW‑EURODRIVE has been synonymous with drive and automation technology expertise for more than 90 years. If you can't afford any more breakdowns, turn to the professionalism and tailored support of our services. Reliable assistance that ensures you can depend on your production processes.

Learn more about solutions for the agricultural industry

About SEW-EURODRIVE

For 90 years now, the owner-operated family business SEW-EURODRIVE has stood for a diverse range of values, including everything from a personal, partnership-based approach, solutions and services to responsibility, quality, tradition, innovation and a whole lot more besides. With our diverse portfolio of drive and automation technology, we move countless applications in virtually every industry. Our 17 production plants and 81 Drive Technology Centers in 52 countries mean we’re at your service on every continent and in every corner of the world. We work reliably and straightforwardly with our customers as equal partners, and foster customer proximity.

Our range of services

When the name SEW-EURODRIVE is mentioned, one of the first things people are quick to mention is "gearmotors", which formed the beginnings of our company. In the meantime, however, the SEW-EURODRIVE name stands for much more, and our range of products and services has grown significantly.

Gearmotors, gear units, motors, components for decentralized installation, electronically controlled drives, mechanical variable-speed gearmotors, as well as drive solutions that involve a lot of engineering. Of course, we shouldn't forget supplementary services and service offerings.

SEW-EURODRIVE ... Driving the world.