Learn key areas of the trailer to enhance your operational efficiency, safety, and overall productivity in feed transport.

Brand Insights from KT Pacer

When it comes to transporting bulk feed, selecting the right trailer or body configuration is key for operational efficiency and safety. Let’s explore some key areas of the trailer or body to help you make an informed decision.

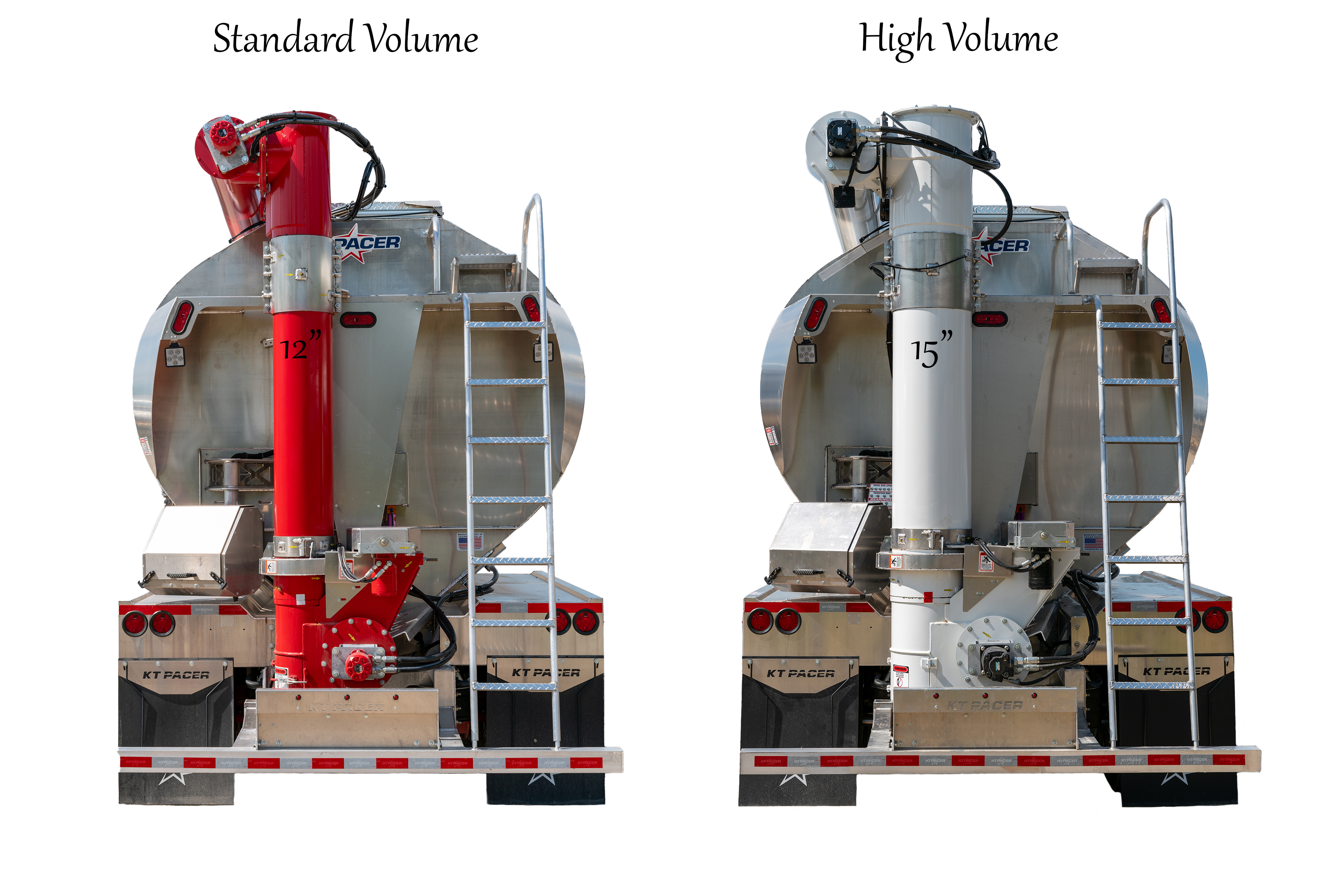

High Volume vs. Standard Volume Auger Group

When choosing between a high-volume and a standard-volume auger group, here are some outlying factors to consider. Distance from the mill to the grow barn. Generally speaking, the high-volume auger group will off-load the feed approximately 3-5min faster than the standard volume auger group. Depending on your travel time and mileage to and from the feed mill, does the reduced time to off-load feed provide the ability to deliver additional load(s) in a day? If it does, then there is a benefit to increased loads per day from a revenue standpoint. If it does not, then staying with the standard auger group will reduce weight and add payload, as well as provide a lower investment cost on the trailer.

Depending on the feed type, a high-volume auger group may provide increased efficiency when off-loading lighter weight / bulky feed product by providing higher area of volume to move the product through.

There are benefits to both systems so understanding how they perform and the impact to your feed haul business will help determine the best choice for your business.

Biosecurity

Biosecurity is a top priority for many grow operations, and your feed trailer or feed body can play a significant role in maintaining it. Modern feed trailers are designed with biosecurity features that aid in reducing the potential for contamination. These include sealed compartments, smooth interior surfaces, a steeper angle for the bottom half of the trailer side sheets, clean out ports for auger groups, and air service ports to blow residual feed off the unit.

Many OEMs offer an on-board disinfectant system that can be activated before entering a facility to help mitigate risks associated with cross-contamination, protecting both the feed quality and the health of the livestock.

Gate Designs

The design of the gates on a feed trailer can significantly impact the ease and efficiency of unloading. Various gate designs are available, and matching the gate design based on the feed type is key.

Gates can be open/closed manually or by using air or electrical actuators. Air or electric actuated gates offer ease of use and can be set to open at various stages to aid in faster unloading times by maintaining a consistent flow of feed to the auger system. Manual gates, while potentially more cost-effective, require more labor and can be slower to operate. Selecting the right gate design depends on your specific operational needs and the volume of feed being transported.

Trailer Profiles and Low Center of Gravity

The profile of your feed trailer is another crucial consideration. The tank profile is often matched to maximize payload based on volume and weight density of the feed being hauled.

Many OEMs also offer a low center of gravity trailer designed to provide increased stability when transporting heavy loads. A lower center of gravity trailer reduces the risk of tipping, providing transportation over various terrains.

In summary, selecting the right bulk feed trailer or body involves evaluating your specific needs regarding volume desired payload, biosecurity, gate design, technological features, and trailer stability. By carefully considering these factors, you can enhance your operational efficiency, safety, and overall productivity in feed transport.

For more detailed insights and the latest innovations in feed trailer design, visit KT Pacer's offerings at KT Pacer.