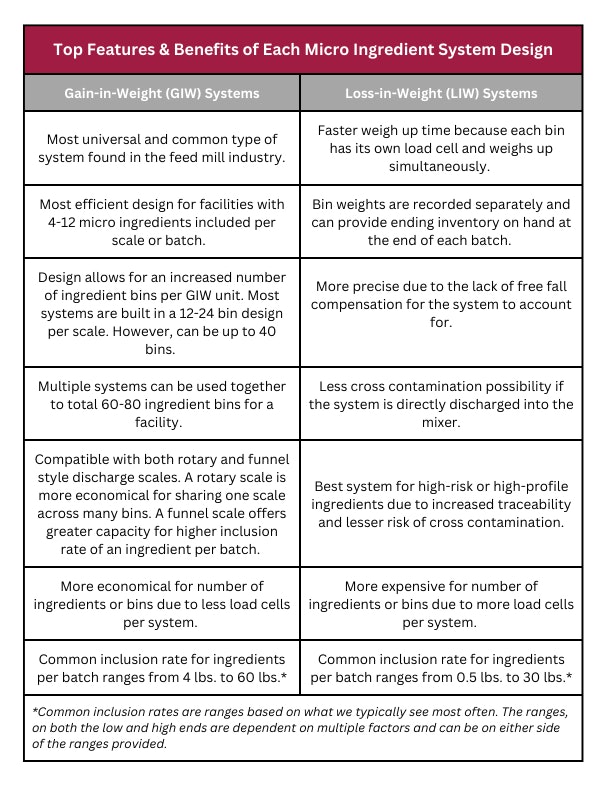

When it comes to choosing a micro ingredient system for your facility, there are multiple factors to consider. Space, budget, labor, number of micro ingredients, storage capacity, and the list goes on and on. While each system is ultimately customized for each facility, gaining a basic understanding of the differences between gain-in-weight (GIW) and loss-in-weight (LIW) systems will help your team narrow down your search from the beginning. Below is a list showcasing the top five benefits and features of each of these systems.

While the chart above gives a brief overview of the features and benefits of the different type of micro ingredient systems, it is important to keep in mind that with customization, each bin can be designed to meet the accuracy, speed and storage capacity for a specific ingredient or mill. Worried about sticky, fine or dusty products? There are multiple different design options such as adding vibrators or air agitation or auger designs and materials that can help with bridging or tough to move materials.

Interested in talking through specifics with one of our salesmen? Contact our team at Easy Automation to discuss your specific facility and needs and we’ll help you build exactly what you need. Visit www.easy-automation.com or call 507-728-8214 and ask for our sales team. We value your partnership and look forward to solving your equipment and automation challenges with you.

More Resources from Easy Automation