Directory

- Aeration, Drying & Storage

- Conveying & Material Handling

- Dust Control & Explosion Prevention

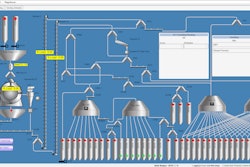

- Engineering, Design & Construction Services

- Feed Ingredients & Additives

- Feed Milling & Grinding

- Feed Mixing & Batching

- Grain Cleaning, Testing & Analysis

- Maintenance

- Millwrights

- Operations Management, Consulting & Financial Services

- Safety & Rescue

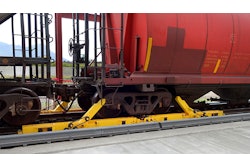

- Transportation

- Weighing & Bagging

Featured

Aeration, Drying & Storage

Conveying & Material Handling

Dust Control & Explosion Prevention

Engineering, Design & Construction Services

Feed Ingredients & Additives

Feed Milling & Grinding

Feed Mixing & Batching

Grain Cleaning, Testing & Analysis

Maintenance

Millwrights

Operations Management, Consulting & Financial Services

Safety & Rescue

Transportation