Dr. Chris Cloney, managing director at DustEx Research Ltd., now offers its 2020 Mid-Year Combustible Dust Incident Report.

DustEx Research Ltd. was founded in 2016 with the goal of seeing a year with zero dust explosion fatalities by 2038. To achieve that result, Dr. Cloney and his team have been publishing resources designed to increase awareness and inspire change in industries handling combustible dust. One of them is the semi-annual Combustible Dust Incident Report, which analyzes the materials, equipment, and industries involved in tracked incidents across the globe.

Report highlights

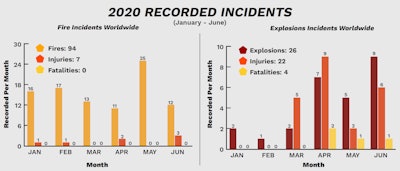

According to the most recent report, all combustible dust-related fatalities during the first half of 2020 were due to dust explosions. Of those injured, 76% were hurt in explosions while 24% suffered injuries in fires. At least three incidents (two in the U.S. and one in Canada) caused over $1,000,000 worth of property loss.

Regarding affected industries, agriculture and wood processing accounted for 43% and 31% of the reported incidents, respectively. Food products, which include agricultural output, were involved in 41% of the tracked fires and explosions while agricultural equipment like silos, grain dryers, and grain elevators feature prominently in the list of equipment involved.

The report includes an interview with Dr. Suzanne Smyth, managing engineer with Exponent’s Thermal Sciences Practice. Dr. Smyth, co-author of Lessons Learned from a Milling Explosion, discussed a grain mill explosion investigation that she had been involved in and recommended ways that managers can avoid incidents when starting up or shutting down equipment.

Safety Tips for Grain Handling Operations

Grain dust fires and explosions are frequently severe and can damage equipment, cause downtime, and lead to injury or death. Below is an overview of recommended measures for controlling grain dust emissions and buildup.

- Conduct a regularly scheduled dust hazard analysis (DHA). Under NFPA 652, all facilities were required to complete a DHA by September 7, 2020 and complete a follow up review or renewal every five years afterward.

- Using proper dust collection equipment. A qualified professional will recommend the right dust collector for the type and volume of dust produced.

- Closer attention to housekeeping: This includes cleaning away any dust accumulated during daily operations and places where fugitive dust could accumulate, such as false ceilings

- Routine equipment inspection and maintenance: Checking all equipment for safe and proper operation and ordering maintenance, repairs, or replacements promptly when necessary.

- Control of ignition sources like sparks and open flames. If ignition sources are present, only use housekeeping methods that do not create dust clouds.

- Empower employees to detect and report unsafe conditions. Facility owners and managers should encourage their teams to bring any potentially dangerous issues to their attention.

Click here for summary of the incident report or download the full report here.

Related Reading

2019 Combustible Dust Incident Report Released

For more information, visit the Dust Safety Science Platforms

DustSafetyScience.com is an awareness platform tracking combustible dust incidents around the world.

DustSafetyAcademy.com is a training and education platform helping industries understand and learn about combustible dust fire and explosion hazards.

DustSafetyProfessionals.com is a vendor connection platform helping to connect you with the right service and equipment providers to make your facility safe.