increased its attention to grain handling facility enforcement, particularly Permit-Required Confined Space(s). With the presence of a PRCS comes employer responsibility to evaluate their facility and adhere to certain OSHA safety standards. If neglected, the facility is susceptible to citations.

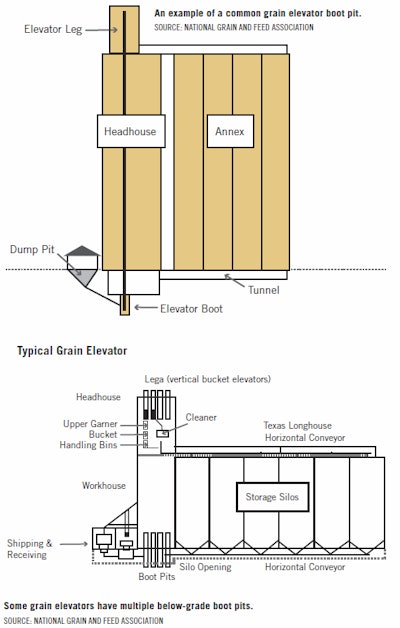

Unfortunately for grain handlers, it is not always clear whether a part of their facility meets the definition of a PRCS. This is especially true when it comes to boot pits, spaces primarily used to house elevator equipment.

In response to OSHA’s increased efforts to classify boot pits as a PRCS, the National Grain and Feed Association’s Safety, Health and Environmental Quality Committee recommended that proactive measures be taken and a guidance tool be provided. Thus, the “Permit Required Confined Space/Boot Pit Evaluation Guide for Grain Elevators” was created last year.

According to Jess McCluer, NGFA’s director of safety and regulatory affairs, “This document provides a better outline on what procedures to follow, in order to determine if a boot pit should be labeled as a confined space or a PRCS.” The document was modeled after OSHA’s eLaws Confined Space Advisor, guidance and the rule-making record to ensure regulatory accuracy, serving as an unofficial reference.

What is a boot pit?

Boot pits are used to house elevating equipment for a grain handling facility. This includes conveying materials like bucket elevators and miscellaneous equipment such as sump pumps, collection systems and lighting. Most boot pits are below grade and require periodic entry for general housekeeping and equipment inspection. Some can be found in “priority housekeeping areas” that include floor areas within 35 feet of inside bucket elevators.

Qualifications of a confined space

In order for a boot pit to be labeled as a PRCS, it must first be classified as a confined space. To qualify as such, all three of the following characteristics must be true:

1.Not designed for continuous human occupancy. The space is not intended as a place of regular work and therefore is not supplied with ventilation and other conditions necessary to support life.

2.Limited or restricted means for entry or exit. This includes any space requiring entrants to exert unusual effort to enter or leave (i.e., crawl, climb, twist, be constrained in a narrow opening or lengthy path, climb a ladder) or where the entrance may become sealed against opening from the inside.

3.Large enough and so configured that an employee can bodily enter and perform assigned work.

Is your boot pit a confined space?

As long as adequate ventilation is in place, a boot pit is considered fit for continuous human occupancy. Most boot pits have naturally acceptable ventilation, but some facilities utilize additional ventilation as well (i.e., pneumatic dust collection system). Boot pits are usually set up for regular entry with no special operating conditions (e.g., emptying a grain bin). Depending on the facility, a boot pit may have limited accessibility. Consider three questions:

1.Does the boot pit have a standard-sized door?

2.Does the employee have to climb a ladder or articulated stairs or use other unusual means of escape that would make it more difficult than normal stairs?

3.Does the employee have to crawl or maneuver around equipment to escape?

Additionally, the distance/time it takes for an employee to exit a boot pit could affect whether it is considered a confined space or not (e.g., a tunnel), although OSHA has offered minimal insight into these situations.

What is a PRCS?

Once a boot pit is confirmed as a confined space, it must meet at least one of the following criteria to be considered a PRCS:

1.Contains or has the potential to contain a hazardous atmosphere, one that exposes employees “to the risk of death, incapacitation, impairment of ability to self-rescue, injury or acute illness.”

2.Contains a material that could engulf an entrant.

3.Has an internal setup so that an entrant could be trapped by inwardly converging walls or by a floor which slopes downward into a smaller cross-section.

4.Contains any recognized safety hazard. Physical hazards, such as grinding, exposed moving parts or trip/fall hazards; non-atmospheric chemical hazards like corrosives; electrical hazards; or issues like rodents, poor visibility and weather hazards.

Is your boot pit a PRCS?

Boot pits do not usually contain the hazards listed under OSHA’s “hazardous atmosphere” list. The presence of flammable gases, vapors or mists in excess of 10% of its lower flammable limit are not commonly present, nor is airborne combustible dust at a concentration that meets or exceeds its lower explosive limit. Boot pits would not typically have an atmospheric oxygen concentration above 23.5%. The presence of a Subpart Z substance does not automatically classify a space as a PRCS.

Moving forward

Since the release of the guide in September 2013, NGFA has seen a strong response from its members.

“The feedback has been positive from the members that I’ve talked with who are a part of our SHEQ Committee, and from the members I’ve spoken with at seminars,” said McCluer. “The document has significantly raised attention to the issue.”

NGFA is taking steps to inform its members of PRCS and grain handling facility guidelines through safety seminars, newsletters and webinars. A member of the SHEQ committee will present a session on the topic at NGFA’s annual Safety Conference in Kansas City, MO.

Given the nature of boot pits and the variation seen between grain handling facilities, a one-size-fits-all approach is simply unattainable. Rather, employers can use NGFA’s guide as a reference to proactively determine whether their facility could classify a boot pit as a PRCS.