What is your management style? Do you make a decision and stick with it through “thick or thin,” … or are you willing to be flexible and compromise? Is there a right strategy? What are the pros and cons of rigidity vs. flexibility?

Some management experts have called the 1970s the “Decade of Productivity,” and have referred to the 1980s as focused on total quality management (TQM). Some of these same folks have characterized the 1990s and 2000s as belonging to “flexibility.” Dr. Sumer Aggarwal — retired dean of the University of Massachusetts College of Management — authored an article titled “Flexibility Management: The Ultimate Strategy.” He states that “restructuring, re-engineering and reinventing are simply methods for making a company flexible enough to respond to the ever increasing and fast changing needs of customers.”

From a business point of view, flexibility means the ability to meet the needs of the market without too much cost, time or effort, performance or organizational disruption. It may involve making changes in your operations. The need for flexibility often originates with customers. As market competition heats up, customers demand customized products, broader and changing product lines, fluctuating order sizes, multiple quality levels, quick delivery response and a variety of price levels. We will delve into some of the things to look at related to flexibility in more detail below.

External flexibilities

Experts indicate that external flexibilities can be measured along three dimensions. The first is range. Range can be defined as your range of size, volume and products. In the feed and grain industry this would include the size of your market, the volume of grain you can handle (bushels of storage capacity) and/or your feed manufacturing capacity (tons). Additionally, this relates to the scope of your product line (feed, farm supplies, etc.). Flexibility requires a sharp pencil here as it does with the other dimensions. Almost all of these sorts of choices involve trade-offs. Expansion of product lines are only worthwhile if they generate sufficient inventory turns, and can be financed appropriately. This can be gauged by analyzing your market and the competitors you face.

A second measure of external flexibility is mobility. Your feed and grain business can attain mobility in space, cost and capacity. How mobile is your business regarding the physical footprint your plant takes up? Mobility here may involve looking at such flexibility as expansion via modular pods to reduce the expense of permanent facilities. Cost mobility includes looking at the source of your costs. Costs are split between fixed and variable costs. Are there ways you can reduce your fixed costs? Labor, buildings and equipment top the list of fixed costs. Can any of these be contracted out? As above — these choices involve trade-offs which need to be analyzed.

The third dimension is uniformity; in addition to being flexible, a company needs to provide uniform quality. To be cost effective, you need to attain uniform yield rates. For simplicity, you need uniform processes, methods, procedures and systems. All of this pushes against flexibility. However, we would argue that your feed and grain business can work to be “uniformly flexible.” You do not have to cut corners on quality — you just need to be prudent in determining how flexible you can afford to be without sacrificing excellence.

Dr. Aggarwal indicates there are several other elements that can be helpful in promoting external flexibility of one type or the other, and he calls these “soft flexibilities.” These may include:

- Organizational structure flexibility — would a team approach to a problem or a market work better than a hierarchical approach with supervisors, etc.?;

- Decision-making methods flexibility — would delegating decision making to lower levels be faster and more efficient? Or would a consensus approach among lower level managers provide hybrid vigor and better buy-in from these people?;

- Job-design flexibility — job sharing or cross training can often boost morale and bring innovation to your business;

- Management perception about the need for change — this is up to you! Change is all around us, and sometimes we don’t even see the need for change. Be open to new views and read about demographic and industry changes, and change can often be good for you and your business.

Internal flexibilities

Aggarwal suggests that in order to satisfy customer needs, there is a variety of management “levers” (mechanisms) which can be used for manipulating the “internal flexibility” of operations. These include:

- Sequencing flexibility — are there efficiencies you can obtain by looking at the sequencing of your operations? Typically in the feed and grain business, the ordering of operations ispretty straightforward. Raw commodities are received by truck or rail, elevated and stored in grain bins and then loaded out to feed mixing or to truck or rail in the case of commodity grains. However, it may be worthwhile to look at how you handle products to see if additional flexibility might improve the opportunity for cost reduction or additional sales. For example, you might consider manufacturing larger batches of particular feeds. While this is perhaps more efficient, it generates a need for storage — either bag or bulk;

- Routing flexibility — like the sequence of operations discussed above, take a look at your routes. Are they the most flexible and/or efficient?;

- Labor flexibility — can you utilize part-time labor, which might reduce your benefit costs for permanent employees, and would thus allow you to not be “long” on labor during slow periods;

- Raw-materials flexibility — while the definition of “least cost rations” in the feed business implies the use of appropriate and cost-efficient feedstuffs, it is always worth reviewing sources of feed and looking for “opportunity” feed ingredients.

Flexibility with suppliers

Professor Aggarwal analyzed the total chain of acquisition processing and distribution functions in his study of flexible management.

He concludes that companies need flexibility “levers” between adjacent stages and also within each of the stages. This implies flexibility at your interface with suppliers.

He states that a company can work closely with suppliers to obtain flexibility at this interface through a variety of methods:

- Push for shorter lead times;

- Use faster transport systems;

- Write short-term contracts with suppliers (which can provide you flexibility to change if needed); and

- Streamline your ordering, receiving and other paperwork.

Flexibility at the interface with your customers

As mentioned earlier, the variety of customer demands is the primary reason for the focus on flexibility. However, only a few actions are possible at this particular interface. Most of the flexibility is achieved either internally with the variety of your equipment, methods, procedures, structures and systems, or with certain collaborative and complimentary arrangements with your suppliers or other companies within the industry. However, there are some actions that can be undertaken to improve the flexibility at this interface as well. Aggarwal cites:

- Use a powerful information link with your customers — e-mail; your website which can provide updated market information; and grower/feeder meetings when appropriate;

- Obtain quick feedback from your consumers — this allows you to regularly take their pulse on changes in their needs;

- Integrate forecasting, planning and control, with a total focus on your customers.

Other methods of obtaining flexibility

Finally, Dr. Aggarwal outlines other ways of obtaining flexibility: through people and their work behaviors, and information systems. Each of these constituents of your feed and grain company overlaps every stage of operations as well as the places where they interface.

People — Humans are your most flexible resource due to their special attributes of social motivation and emotional needs, as well as the ability to feel, learn and adapt. All complex tasks must be performed by humans. Narrow tasks are amenable to automation. People provide flexibility through their alertness and analytical capabilities. Humans can add greatly to flexibility if they are cross-trained; have only a few job classifications; are made responsible for preventive maintenance; are supervised by technically trained and skilled leaders; are motivated, skilled and creative; are free to self-organize themselves into various sized groups, as and when their workload changes; and are empowered, which requires a leap of faith by you as the owner or manager of your grain and feed business.

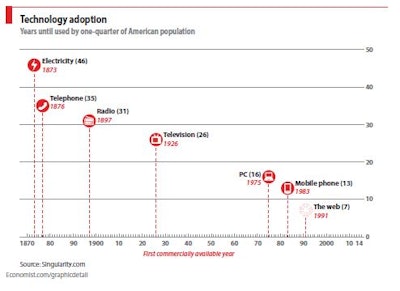

Information — Information resources can provide great support to all the actions and mechanisms used for obtaining flexibility. Fast collection, storage and dissemination of information helps your elevator or feed company arrive at faster decisions and quicker actions. Support provided by decision models and software can improve flexibility. To achieve greater flexibility through information, your company must eliminate redundant data and minimize the total number of interface points within your company information system. Information systems are often very complex and costly because they consist of advanced database management tools, communication networks, a variety of end-user operating tools, data-collection devices and sometimes simulation packages.

Advantages and disadvantages of flexibility

Higher levels of flexibility certainly offer advantages under fast-changing and turbulent market conditions. Flexibility also improves capacity utilization and can provide substantial overall labor savings. Flexibility can fight against randomness and obsolescence. Flexibility can reduce redundancies.

Flexibility, of course, shortens cycle-time, provides labor savings, offers enhanced manufacturing capabilities, and greatly advances the readiness for future installation of flexible automation. However, you as the manager need to constantly guard against the push for flexibility turning into … chaos.

At times, companies may indulge in technology overkill in the name of flexibility, which is a disadvantage. This may be a wasteful expenditure for totally unneeded flexibility. Human resistance can prove detrimental to flexibility. It can only be overcome with communications, teamwork and creativity. Flexibility also works against economies of scale, which can be a disadvantage.

Some conclusions

A flexibility program must not look for big solutions; rather it must break big problems into workable subproblems. Flexibility dictates that you as a manager must not become fascinated with complexity and advanced technologies. It requires rewarding employees who help in reducing complexity, and in enhancing the flexibility of your existing resources.

Above all, remember that without regular training or retraining of employees in problem solving and creativity, flexibility may remain just a slogan. To advance flexibility on a continuous basis, there is nothing superior to nonstop pursuance of a continuous improvement program. Flexibility on a number of fronts can be worthwhile and can contribute to increased profitability and return on investment. The bottom line is that being flexible and searching out flexible strategies can increase your choice set and provide management options that are worthy of consideration.